Innovative, healthy building materials profile: Fibreboard

These days more and more companies are finding ways to reduce their carbon footprint. Concerns about climate change are mounting, and there is a real appetite to take responsibility for this global problem, coupled with awareness that innovative solutions to lighten the carbon load often help improve the bottom line.

Greening Homes has been conscious of its environmental footprint since its inception. We are always looking for top-of-the-line products that help reduce greenhouse gas emissions, which are contributing to climate change, while safeguarding the health of our clients. Often, these products help reduce lifecycle costs as well.

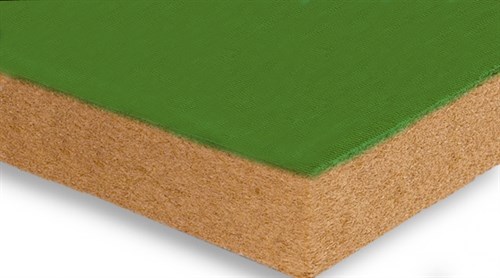

A perfect example of this is fibreboard. Fibreboard can be used for a number of applications, including roofing, insulation, and soundproofing. As an industrial by-product, it’s made entirely from recycled and recyclable wood fibres, and is extremely durable. As such, its energy embodiment is low, meaning that a minimum amount of greenhouse gases were produced to make it. It also helps reduce waste, another important pillar for Greening Homes. Discarded wood is used to make fibreboard.

Fibreboard is used primarily for insulation. While blown in cellulose receives the highest mark for low carbon footprint, fibreboard come in at a close second. It has another advantage. It serves double duty as both insulation and plywood sheathing, helping to reduce costs.

Fibreboard is also permeable, allowing for movement of vapour. Depending on how well the house’s system is constructed, any cellulose insulation responds well to moisture. With cellulose, however, there is a saturation point. If the house’s system is ill-conceived and built, it can be subject to moisture problems and mold, a health hazard.

Fibreboard offers another ecological advantage. It helps sequester carbon. Passive House expert, Chris Magwood writes about this in a recent blog for Endeavour:

“If a building uses plant-based materials in its construction (wood, straw, hemp, cork, bamboo, mycelium and recycled fibres of all kinds), those materials are partially made of carbon that has been taken from atmospheric CO2 and converted by the plant into its cellular makeup. Usually, the carbon in plants is released back to the atmosphere when the plant decomposes (or burns). But if we contain that plant fibre in a building for a long time, we sequester that carbon in the building. It’s the simplest form of carbon capture and storage (CCS); the plants do all the work of pulling CO2 out of the air, and we put them into buildings for a long time.”

We’ve considered using fibreboard products from MSL, a Canadian company. Its SONOclimat ECO4 insulation panel has a thermal resistance value of R4, and excellent permeability to water vapour of 25.9 perms. It’s also provides excellent sound proofing, great for those who are sensitive to noise.

The one downside to MSL is that we would have to buy large quantities, making it a challenge for smaller projects. We are looking at German-based Gutex as an alternative. 475 High Performance Building Supply offers Gutex products in smaller quantities.

Bottom line, fibreboard is a quality product with a small environmental footprint, helping to improve home comfort while reducing construction costs.