LEED for Homes – Best practices for Air Sealing

The air tightness of residential homes in Ontario has increasingly been improved over the past few decades. According to a public 2009 study of 100 new homes, “The average leakage of current housing is 3.14 ACH50”. Of the homes in the study, detached homes registered an average air leakage of 2.82 ACH50, and attached or semi-detached homes registered an average air leakage of 4.33 ACH50.

So, what resources are currently available to learn about and implement residential air sealing best practices in Ontario? The most popular resource for most building related specifications would be the Ontario Building Code (OBC). If we do refer to the OBC for help, little can be found to aid this quest. There are few provincial requirements about air infiltration other than references to the continuity and placement of air and vapour barriers. Subsection 9.25.3 in the OBC includes the word ‘sealed’ 16 times without expanding on how one would accomplish this.

Another resource, and one I draw much inspiration from, is the 2009 LEED for Homes Rating System reference guide. If you consult the guide, you will find under Energy & Atmosphere Credit 3 (EA 3) the requirements for the available air sealing credits (called ‘Air Infiltration’ within the system). The prerequisite for the credit category (EA 3.1) requires a project to achieve 5 ACH50 or less for Toronto’s climate zone. To gain any credit category points, your project must obtain ‘Greatly Reduced Envelope Leakage’ (3.5 ACH50 for Toronto to gain 2 points – EA 3.2) or ‘Minimal Envelope Leakage’ (2 ACH50 for Toronto to gain 3 points – EA 3.3). Again, like the OBC, the rating system only describes the requirements for air sealing (Air Infiltration) credits. The LEED for Homes Rating System is after all – merely a rating system and not a compendium of best building practices.

With the understanding that the average new home build in Toronto can commonly achieve the prerequisites for EA 3.1 and EA 3.2 using conventional OBC building techniques, we will focus on how the case study project below achieved the requirements for EA 3.3.

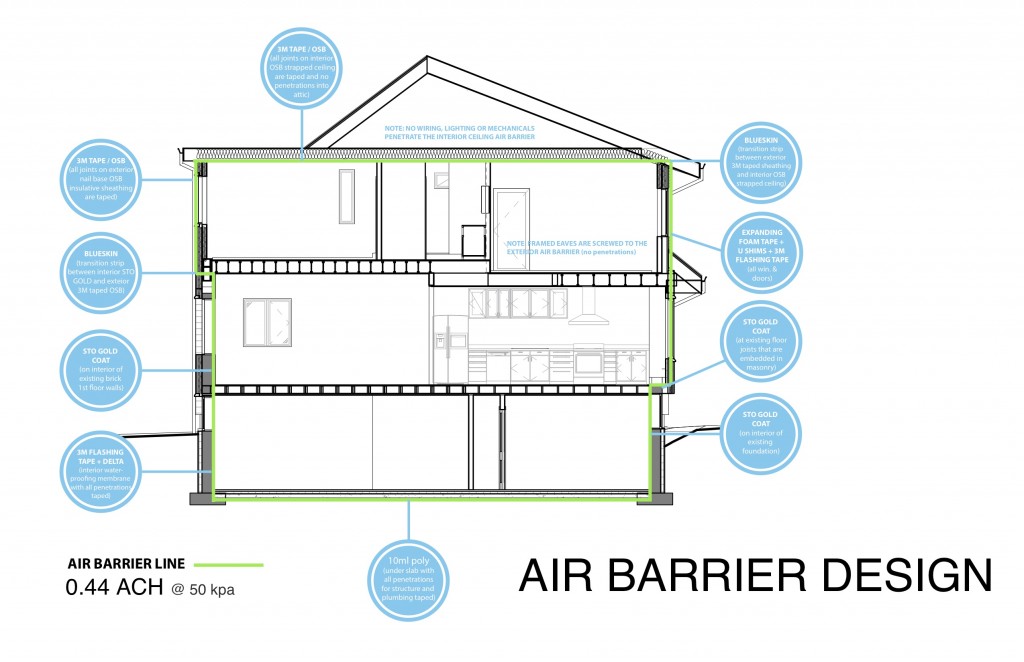

The Beechwood Project is the evolution of a post-World War II bunga- low into a highly-efficient two-storey home: a retrofit that exceeds LEED for Homes EA 3.3 requirements for air infiltration. The project underwent an integrated design process involving the architect, sustainability consultant, mechanical engineer, builder, and other professionals from the high-performance building industry. Through this process, the home’s geometry, glazing, insulation, mechanical system, air barrier detailing and constructability were optimized for energy efficiency, high indoor air quality and low water consumption. Most remarkably, the home received an air tightness level of 0.44 ACH50 upon completion.

• A continuous air barrier was created around the entire house – from below the basement slab to the 2nd floor ceiling:

• 10mil poly sub-slab;

• Fluid-applied air barrier on existing masonry walls. The existing joists embedded in masonry; each joist carefully detailed with air barrier putty and reinforcing mesh;

• Self-adhered, self-sealing membrane used to transition between ex- isting masonry walls and new 2nd storey addition;

• On the new 2nd storey, nail base (polyisocyanurate insulation with an OSB skin) was used as the air barrier. All seams and fasteners were carefully taped to ensure continuity. Nail base was also used for the air barrier on the 2nd floor ceiling;

• All penetrations were carefully sealed with sealant, neoprene boots, or flexible flashing tape depending on their size