ON THE ROAD TO BETTER BUILDING

As the early days of April began unveiling signs of spring, I packed my car, mounted my road bike to the roof rack and headed southeast for Warren, Vermont. Yestermorrow Design Build School was hosting a 4 day Passive House Institute US (PHIUS) Builders Certification course. I had found a small bed and breakfast just under 10 kms from the school and decided to go a couple of days early to get in a few early spring rides. After two 5 hour days in the saddle exploring the hills and valleys, it was time to head down to the hill to begin four days in the classroom.

Day 1

Arriving at just before 0800 in full cycle gear, I was delighted to find a bike rack station under the shelter of the building’s wide overhang. The day started with a quick tour of the facilities. The main office area led to a mezzanine overlooking a wood working shop where a number furniture design students were busy at putting the final touches on their end of semester projects.

The meeting room, which was to be our learning center for the next four days, was graced with a bank of windows and doors on both sides as well as a barn style raised bank on the roof. The main room was filled with tables in rows of V formation and directly adjacent was a small, but very well stocked library. Some 30 odd builders and architects had made the pilgrimage from all over North America – Colorado, Nova Scotia, Seattle, Virginia, Ontario as well as Vermont.

Our instructors comprised of three Passive House US veterans. Dan Whitmore from Hammer and Hand, a Seattle/Portland based design build/company, Adam Cohen, a design builder out of Virginia and Mike Kernagis, a founding member of Passive House US.

Day one was a crash course in PH history and design principles – net zero ready, super insulated, air tight, thermal bridge free, highly efficient mechanicals, balanced ventilation, and high performance windows. We reviewed the basics of building science, moisture and air flow move through an assembly and how and why we need to control this. Many built examples of Passive Houses were reviewed and we were able to discuss what worked and what didn’t.

At midday we broke for lunch. Most of us had bought the lunch package which meant adjourning to the kitchen/dining area to feast on the local organic spread which Heidi, head cook, personally over saw the creation of. It was a chance to mingle with everyone and get a sense of back stories, share building experiences and trouble shoot details.

Day 2

Another day of presentations and discussions surrounding design goals and how to achieve them. Knowledge and understanding of building science is a crucial tool to understanding how a particular assembly may or may not work in the climate region it is designed for.

We explored the pros and cons of several types of foundations, walls, rain screens and roof assemblies. The talk flowed from assemblies to thermal bridges, what they are and how to avoid them. Air barriers are an important means of controlling air movement through the assemblies allowing us to control heat losses, air quality, and moisture movement from unconditional air. In a Passive House building, detailing a good air barrier is critical to obtaining the 0.6 air changes per hour at 50 Pa criteria. An improperly detailed intake and exhaust vent for the hot water tank could make the difference between reaching the 0.6ACH or not.

Towards the end of the day, each of our instructors spend some time discussing projects where a technique that they attempted failed and why.

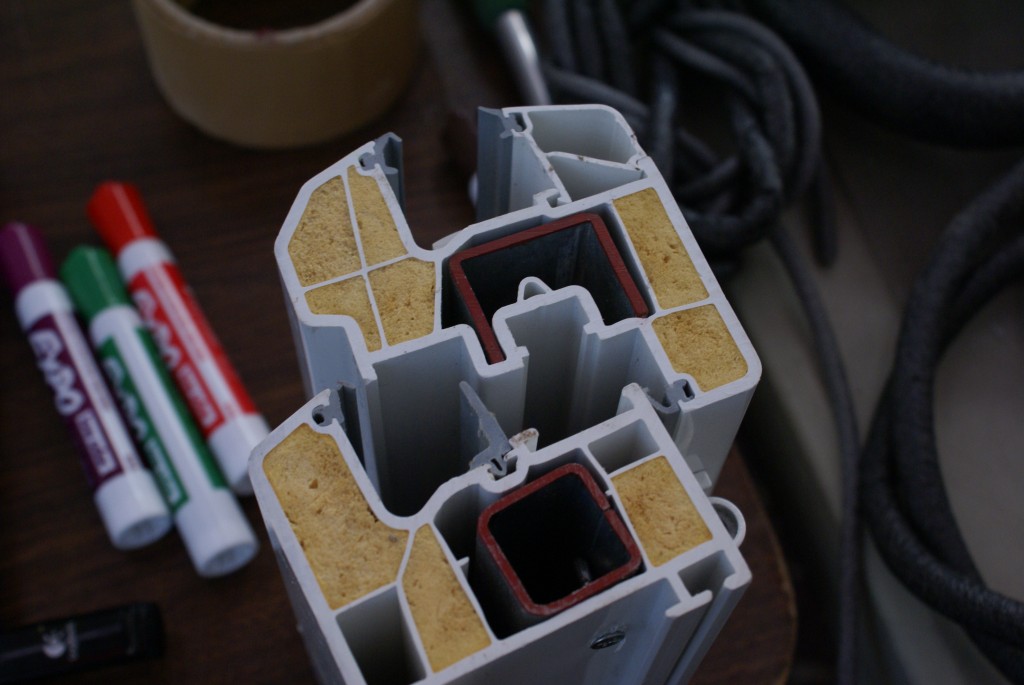

The third day continued the conversations. This time covering Passive House windows, moisture management, air sealing and types of building materials.

Pictured here are examples of Passive House certified windows and a desk littered with all sort of materials including samples of mineral wool insulation, SIPS – structural insulated panels, and various types of air barrier tape including peel and stick membranes and expanding foam tapes.

The day finished with a road trip 45 minutes north to tour an almost complete timber framed passive house with the owner and local builder. You can see in the photo of the window, the green SIGA Risan tape used as an air barrier and the reddish material next to the window frame is a liquid applied air barrier used to seal the exterior sheathing seams and connections.

Day 4

Passive house elements, economics, mechanicals, construction management and PHIUS certification process. It was a lot to cover in one day.

We were given our final assignment – a 7 page take home exam comprising of research, essay questions, and sketches of design details, mechanical layouts, and short answer questions.

Heading home

The following morning I loaded my bike and gear back into my car, which had sat dormant for the entire 7 days in the parking lot of my bed and breakfast. After 7 days, 300 kms of cycling and 32 hours of learning, I turned my car north west for the long 10 hour drive home.

Over the following 3 weeks I spent some 30 odd hours on the take home assignment, submitted it and waited.

By early July I found myself deep into the details and framing of my current project. Vermont was a distant memory already. I turned on my computer to start the day and found an email from PHIUS – The results were in. I had joined the ranks of some 200 Certified Passive House Builders in North America. I believe, as we move forward into a future of rising fuel costs and almost inevitable shortages, unpredictable weather patterns and climate change that the passive house concept will come to play a more significant role in how we build. It all starts on the ground with a small number of builders spreading and sharing knowledge as we strive to build better buildings.

—

By GH Construction Manager, Janette Meyrick